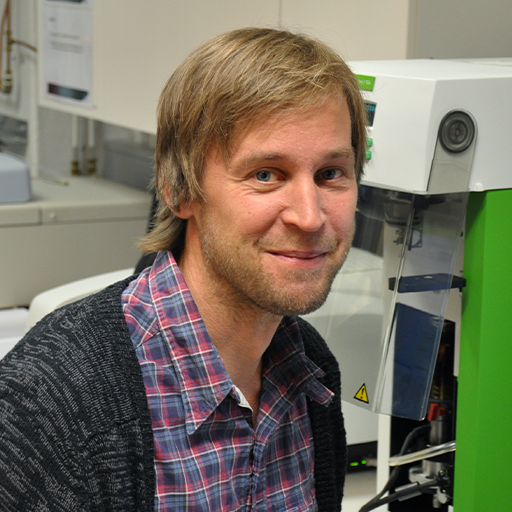

Peter Woodward

Mr Woodward is the founding Director of Quest Associates, which has a long history of delivering specialist facilitation and deliberative discussions, particularly related to the sustainable development agenda. He covers interventions on a huge range of subjects and has wide experience of helping to bridge differing perspectives on challenging issues and has a special interest and expertise in facilitating dialogues and conferences related to the sustainable development agenda. This includes responses to the challenge of climate change; moving to a circular economy, eco-innovation to implementation, quality of life, and governance issues. He moderated the Circular Materials Conference in 2018 and 2021.